Know-how to make and activities

KNOW-HOW

Main Activities

Engineering, design, maintenance, unitary and mass production, specific metrology

- Technical engineering, global service project management

- Project engineering

- Feasibility, Studies, Calculations

- Design, production of controlling and testing tools

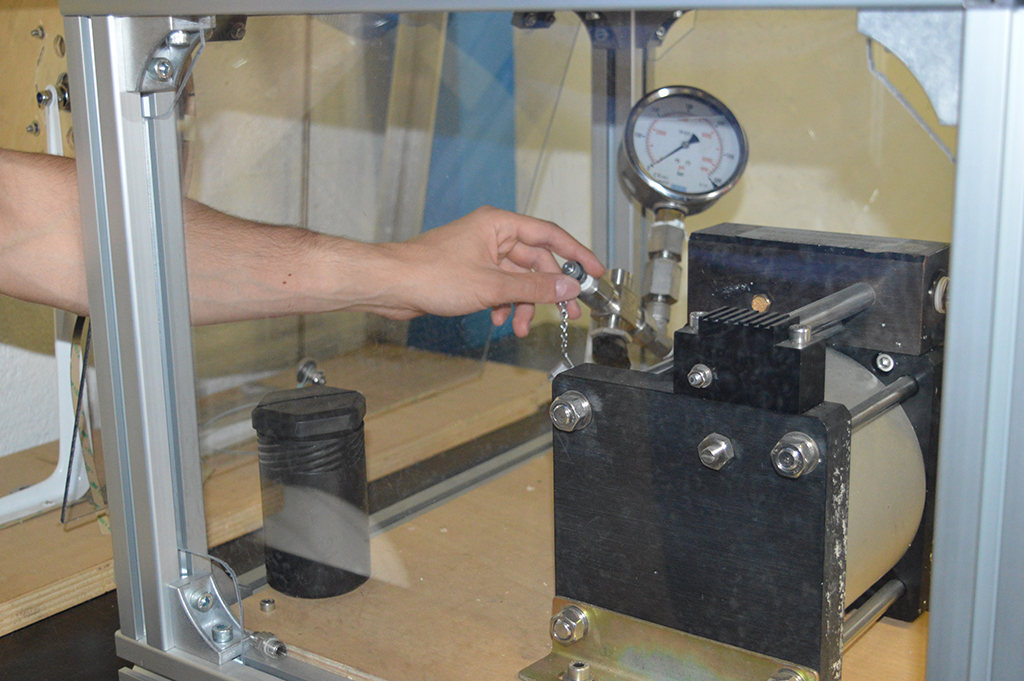

- Design of special machines

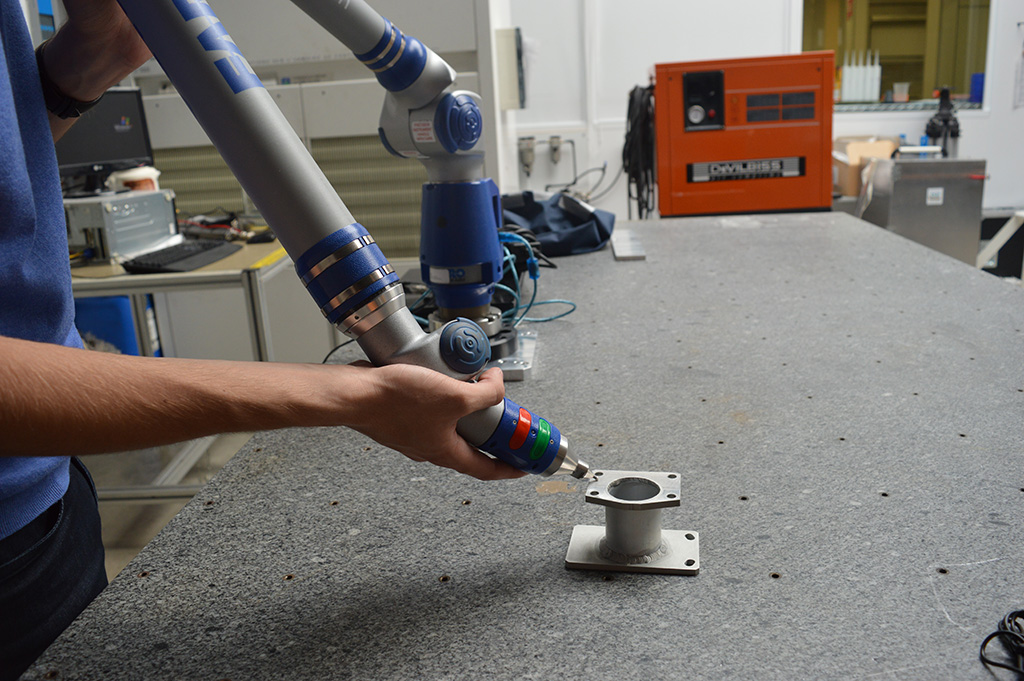

- Robotics

- Mechanical and electrical maintenance of industrial installations

- Optronic systems maintenance

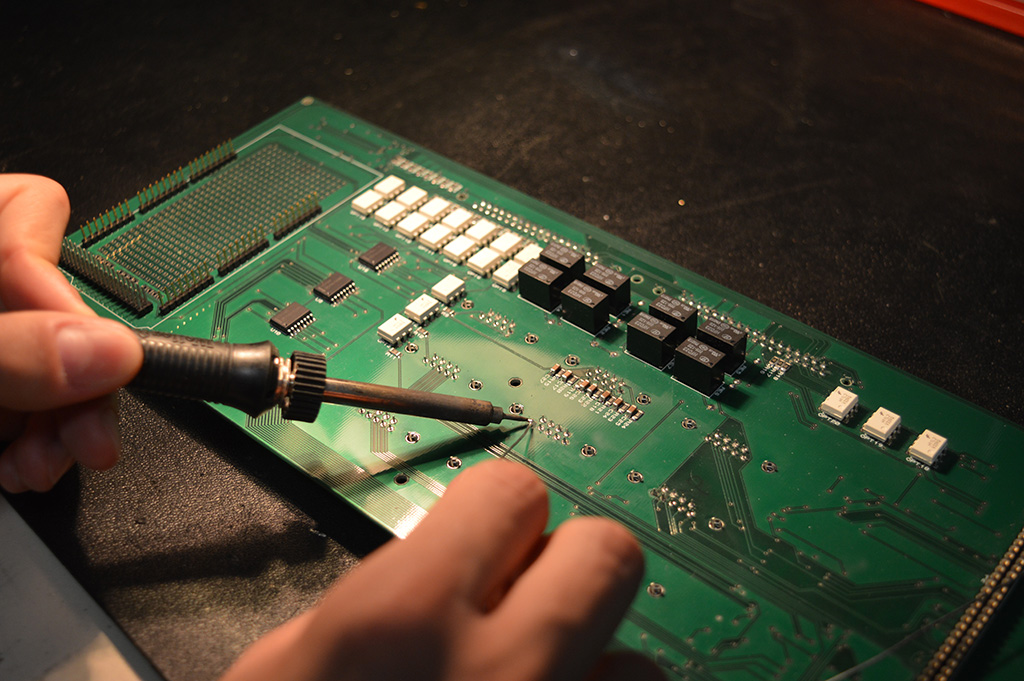

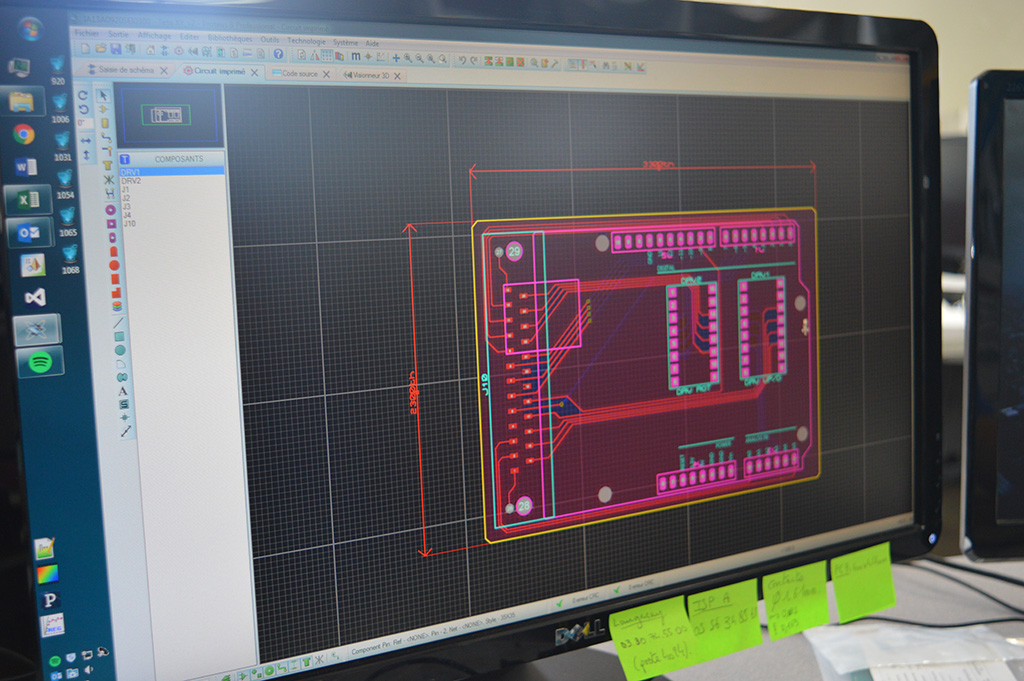

- PCB maintenance

- Structural binding in controlled environment

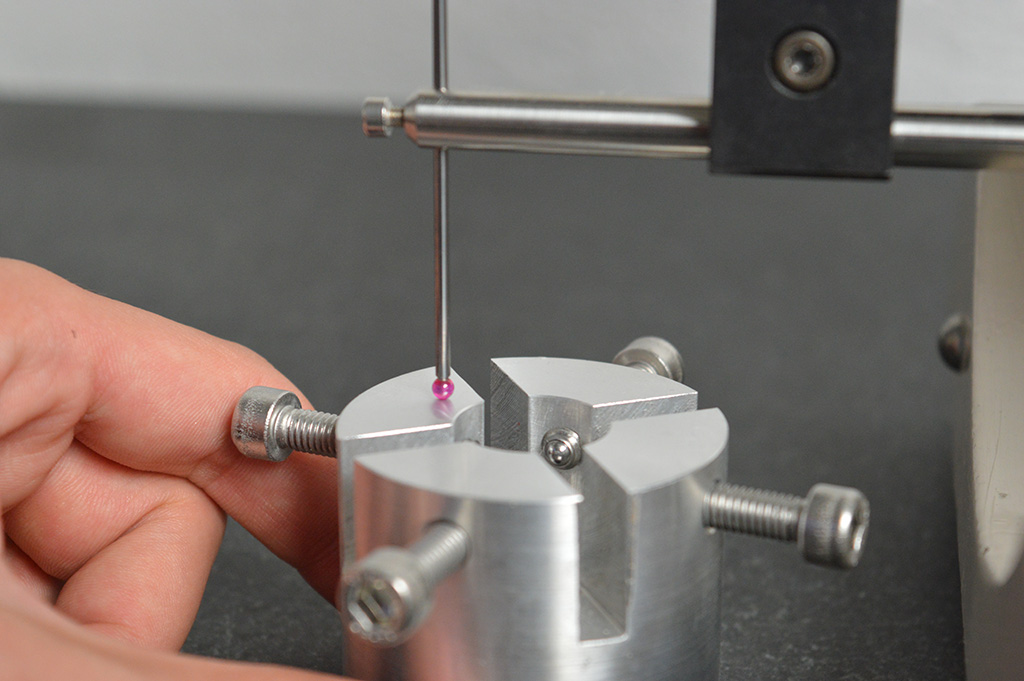

- Specific Metrology

Spécific skills

Mechanics, opto-mechanics, optronics, thermal engineering, automation, vacuum systems, cryogenics, measurements :

- Flight mechanics

- Assembly, sticking, cabling and regulation on systems optomécaniques or optronic in clean rooms

- Measurements and referencing with 3D measure arm

- Special equipment and special machines based on APIs

- Maintenance of electronic boards

Available means

Engineering and consulting

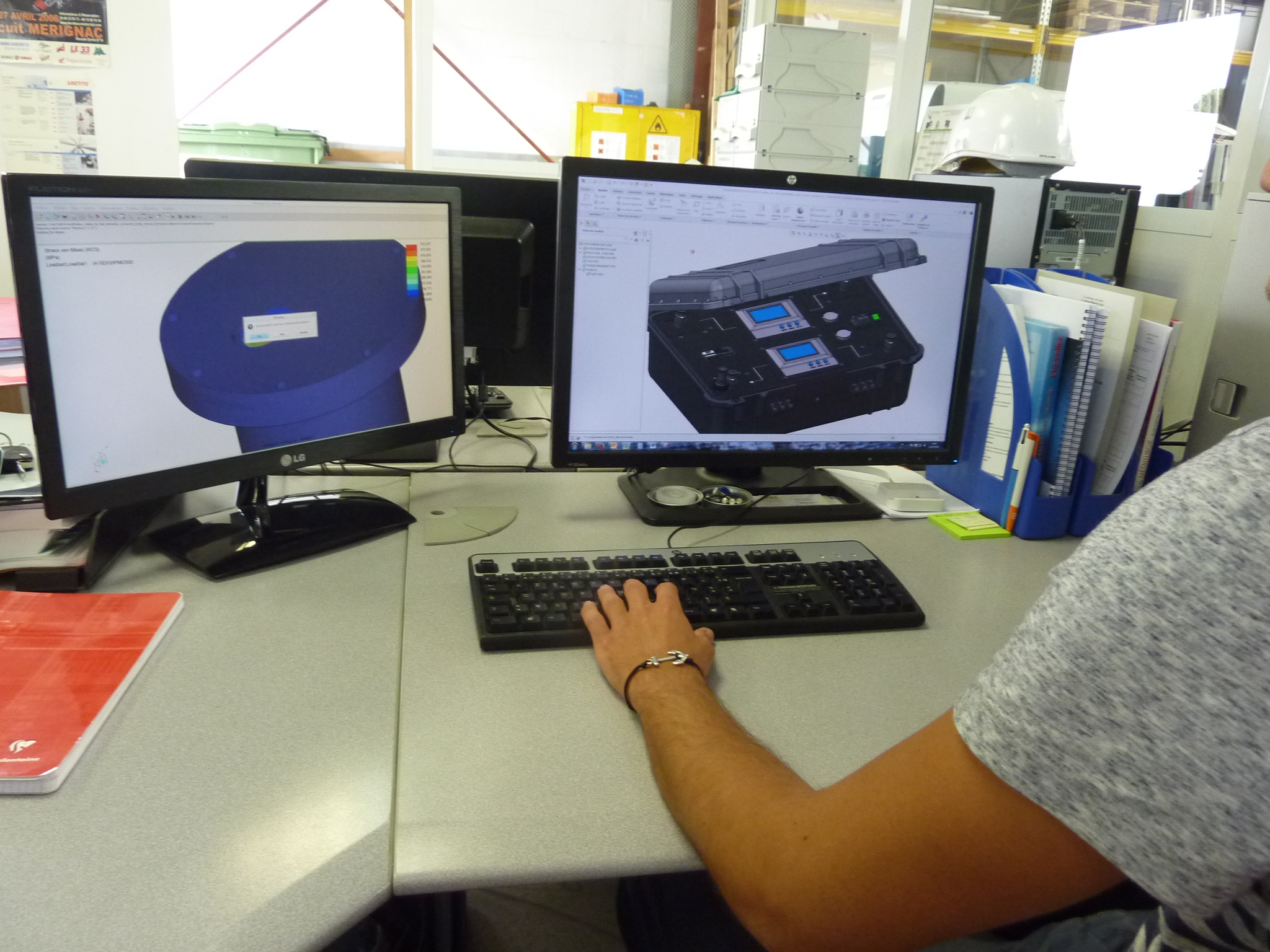

- Mechanical CAD ( 6 stations) CREO II, CATIA V5, SOLIDWORKS,

- Simulation means with Simulate

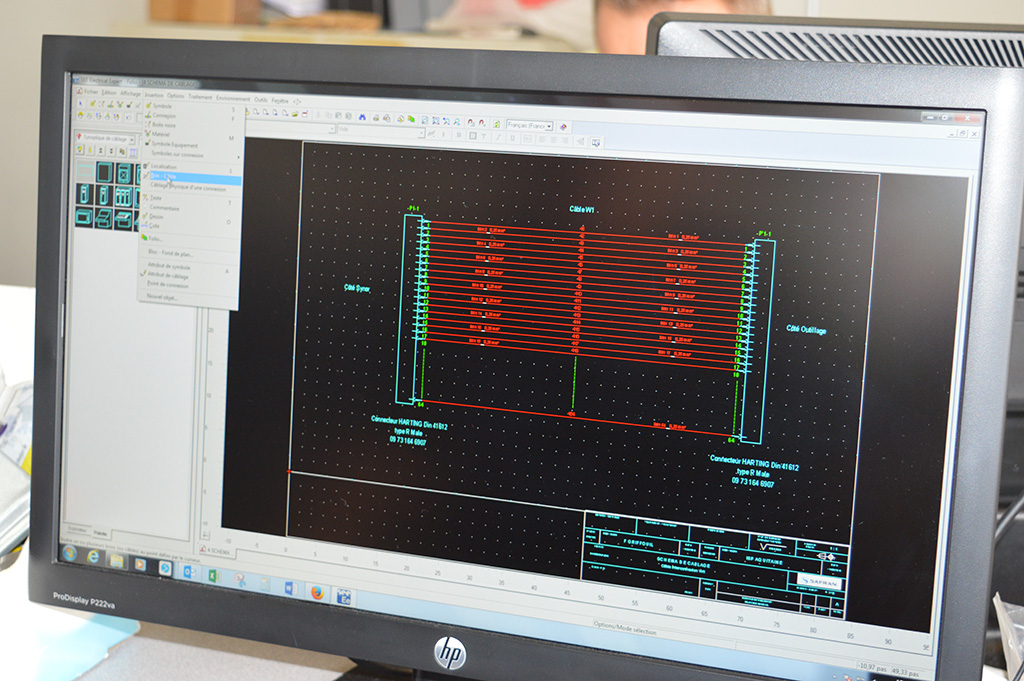

- Wiring with See Electrical Expert

- PLCs: simulations with AUTOMGEN; PL7, UNITRONICS, OMRON, Allen Bradley, Siemens programming

- Programming (piloting or acquisition of data) LABVIEW, Siemens

For more in-depth needs, we can also rely on external software solutions, including the finite element method (IDEAS), simulations (NASTRAN), optical design (ZEMAX), …